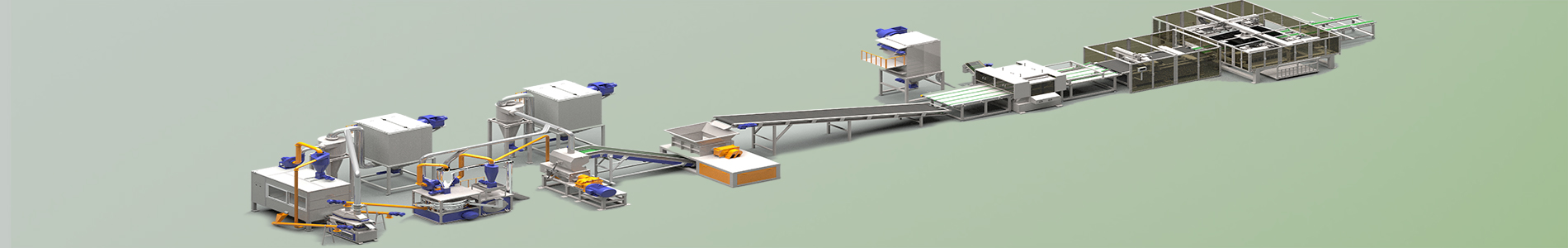

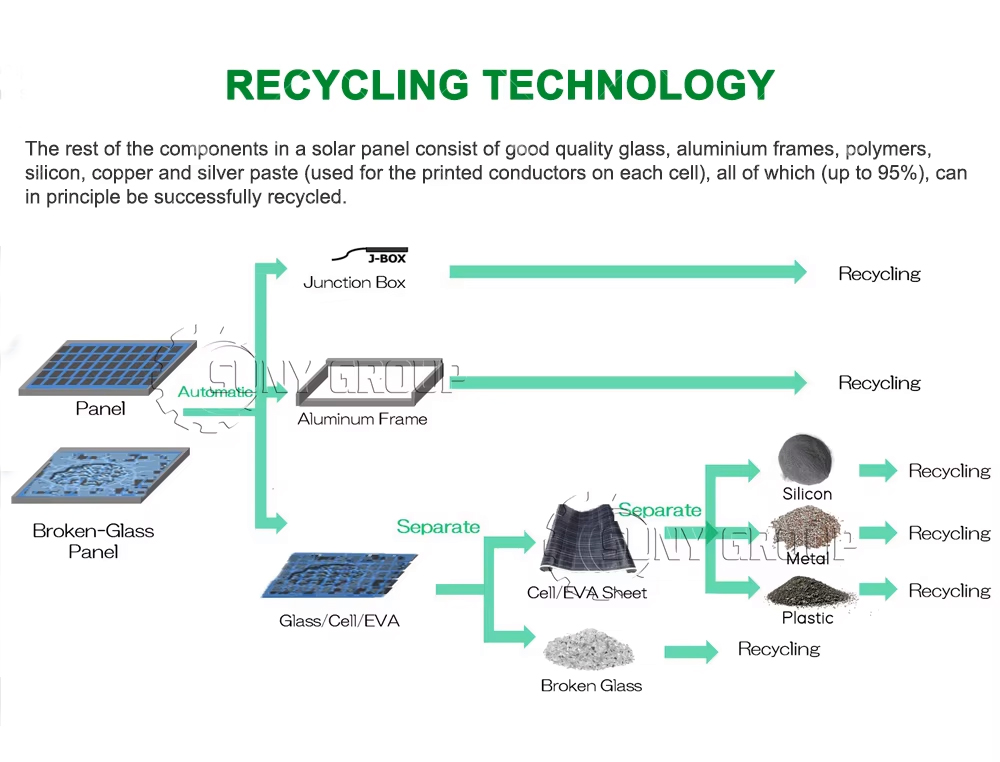

Suny Group’s solar panel sorting and recycling production line is a highly efficient and automated waste photovoltaic module recycling system. It primarily uses physical methods to dismantle, crush, grind, and sort obsolete or retired solar panels.

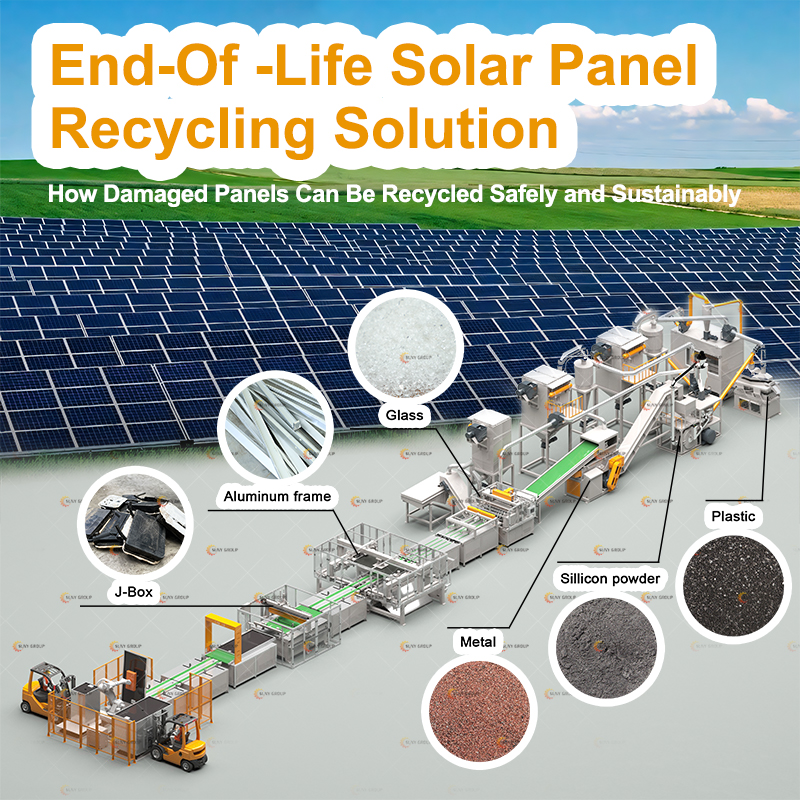

◊Dismantling Stage: First, an automatic frame remover removes the aluminum alloy frame of the solar panels. A glass stripping device precisely separates the tempered glass layer from the panel surface, reducing breakage.

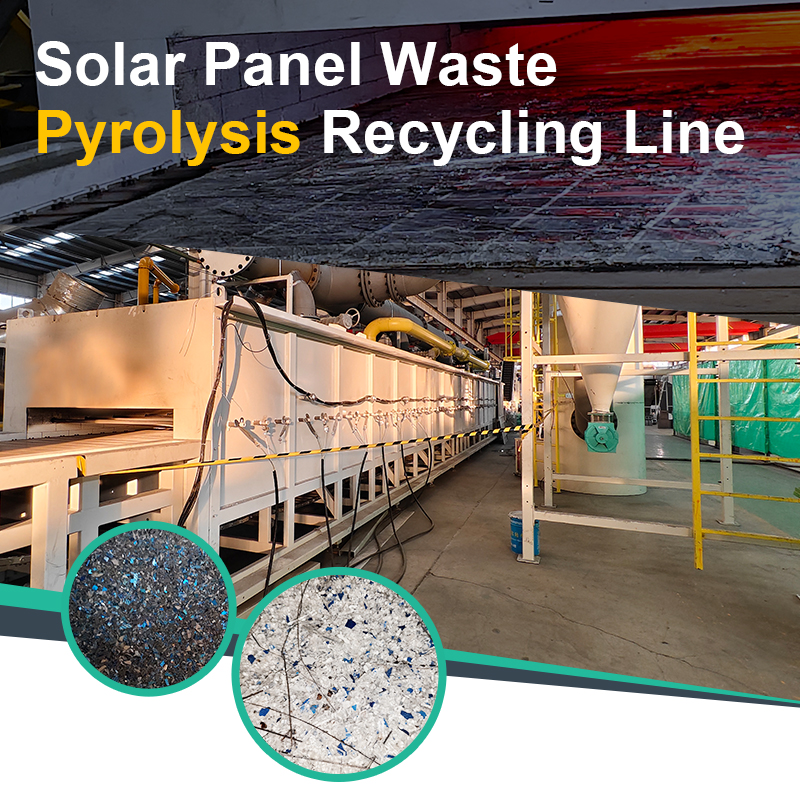

◊Crushing and Grinding: The dismantled modules enter a dual-shaft shredder, crusher, and grinder. Multi-stage crushing controls the particle size of the material, while a pulse dust removal system controls dust, ensuring environmental safety.

◊Sorting and Recycling: Using physical sorting technologies (such as airflow separation and electrostatic separation), the mixed materials are separated into different components such as glass, aluminum, copper/silver metal, silicon powder, and plastics. The recycling rate can reach approximately 95%.

◊Intelligent Control: The entire production line is equipped with a PLC + HMI intelligent control system, supporting real-time data monitoring, remote diagnostics, etc., and is easy to operate and maintain. Suny Group

◊Resource Purity and Output: Recycled aluminum frames achieve 100% purity; glass particles or powder achieve 99% purity; metal (copper, silver) powder achieves approximately 99% purity; silicon powder achieves approximately 80% purity; and plastic achieves approximately 99% purity.

◊Specifications and Performance: Typical models such as the ZYSP-1500 have a capacity of 1,500–2,000 kg/h, a power output of approximately 315 kW, a line size of approximately 36 m × 8 m × 5 m, and a total weight of approximately 11 tons.

Overall, Suny Group’s solar panel sorting and recycling line achieves both high resource recycling efficiency and environmental protection, contributing to the circular utilization of photovoltaic modules.

Recycling process

-

High Automation Level – The line features fully automated feeding, dismantling, shredding, and sorting, greatly reducing labor costs and improving productivity.

-

Efficient Material Recovery – Advanced physical separation technologies enable up to 95% recovery of glass, aluminum, silicon, copper, and silver.

-

Low Damage Rate of Glass – Optimized glass separation systems ensure high-quality glass output with minimal breakage.

-

Environmentally Friendly Process – Equipped with pulse dust collectors, sealed conveyors, and noise-reduction systems to ensure clean and safe operation.

-

Modular Design – Each unit (deframing, delamination, shredding, grinding, and sorting) can be configured independently for different project needs.

-

Durable and Stable Performance – Heavy-duty shredders, crushers, and mills guarantee long service life and consistent output quality.

-

Smart Control System – PLC + HMI control allows real-time monitoring, fault detection, and remote technical support.

-

High Purity of Final Materials – Final outputs such as glass (≈99%), aluminum (100%), metals (≈99%), and plastics (≈99%) meet industry reuse standards.

-

Suitable for Various PV Modules – Compatible with mono-crystalline, poly-crystalline, thin-film, and laminated solar panels.

-

Easy Installation and Maintenance – Standardized structure, clear layout, and quick-access components reduce installation time and simplify daily maintenance.

Next: Solar Double-Glass Panel Recycling Line