Solar Panel Recycling Plant by Suny Group is an advanced and integrated solution designed for the efficient treatment of end-of-life photovoltaic (PV) modules. With the rapid global expansion of solar energy installations, large volumes of waste solar panels are expected in the coming years. Suny Group provides reliable recycling technologies that help recover valuable materials while meeting environmental and regulatory requirements.

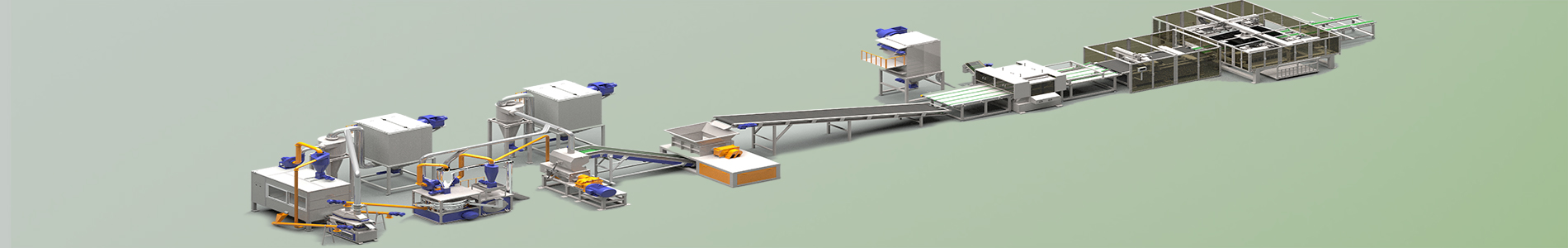

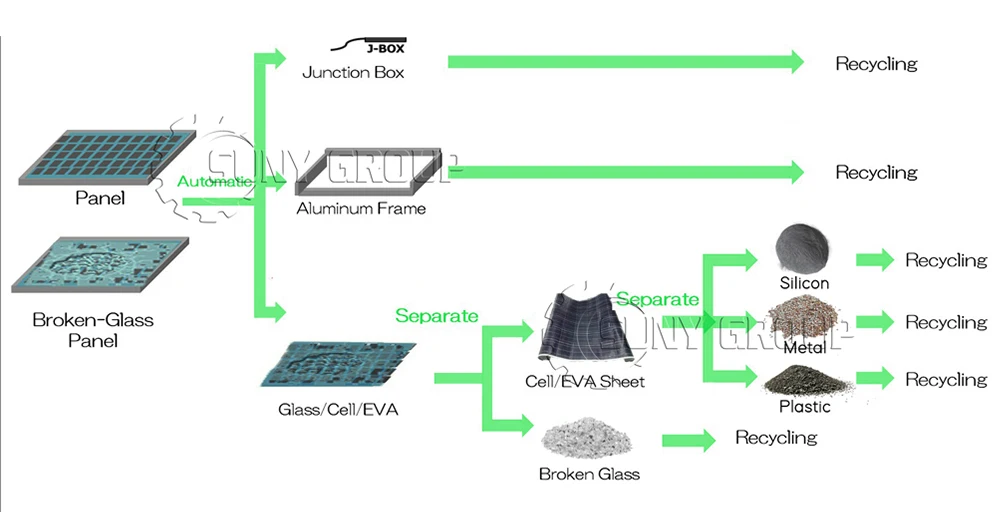

The solar panel recycling plant developed by Suny Group is suitable for crystalline silicon solar panels and can handle complete modules including aluminum frames, junction boxes, glass, silicon cells, plastics, and metals. The plant is designed with a modular structure, allowing flexible capacity configuration according to customer needs, from pilot-scale operations to industrial-level recycling facilities.

The recycling process typically starts with solar panel dismantling, where aluminum frames and junction boxes are removed to recover high-purity aluminum and copper. Next, the panels enter a crushing and shredding system, which reduces the size of the laminated glass and silicon layers. Advanced separation technologies, including screening, magnetic separation, and air separation, are used to efficiently separate glass, metals, and mixed materials.

Suny Group’s solar panel recycling plant features low energy consumption, stable operation, and high material recovery rates. The recovered glass can be reused in construction or glass manufacturing, while aluminum and copper are returned to the metal recycling industry. Silicon-containing materials can be further processed for secondary industrial applications, supporting a circular economy in the renewable energy sector.

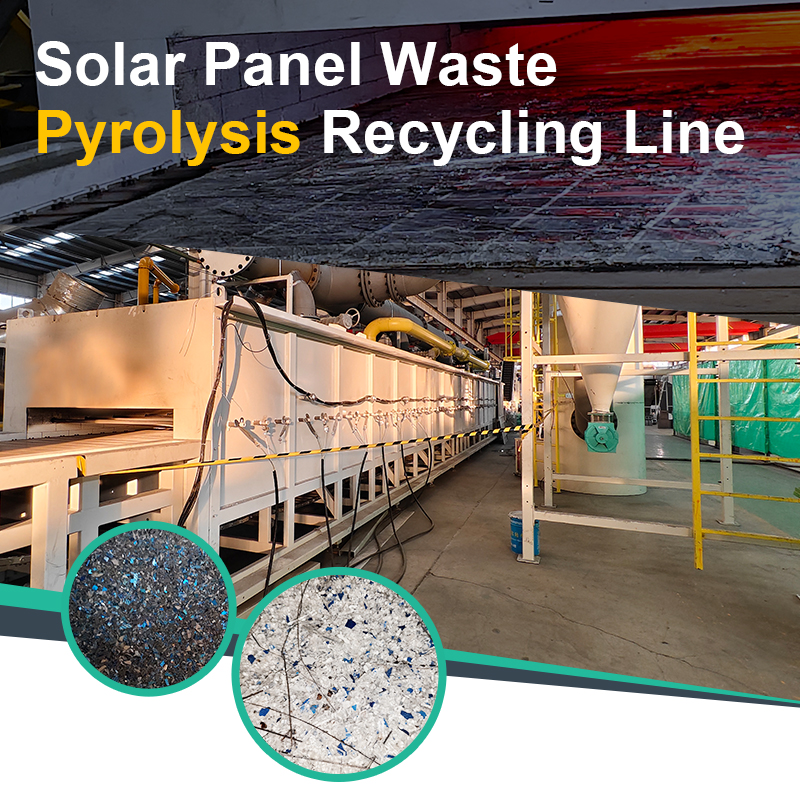

RECYCLING TECHNOLOGY

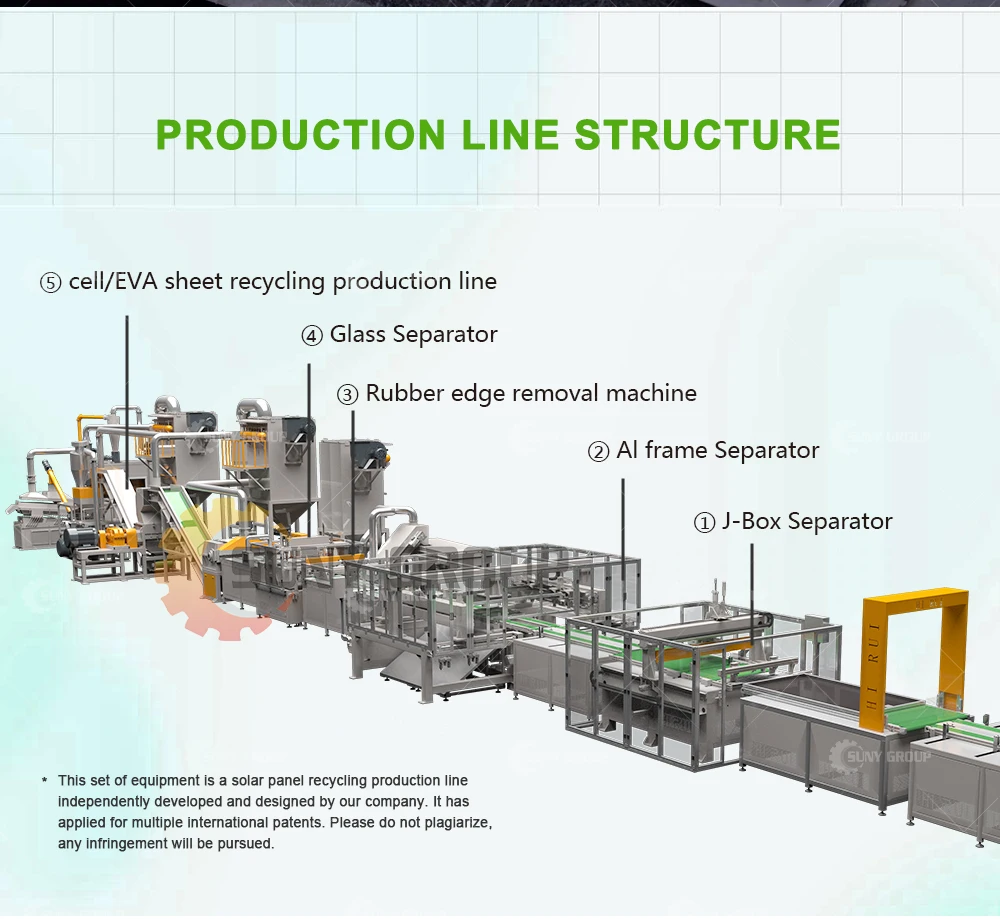

Our advanced Solar Panel Recycling Machine ensures continuous, high-efficiency material recovery through the following steps:

1.Initial Dismantling: The process begins with specialized machines. The J-boxre- moving machine removes the junction box from the solar panels. Subsequently, the Aluminum frame removing machine is used to accurately separate the aluminum frame from the panel edges.

2.Glass Separation: The panel proceeds to the Glass removing machine. This unit is crucial for mechanical separation, designed to remove the majority of the glass from the panel surface.

3.Shredding and Crushing: The pre-treated photovoltaic panels (with aluminum frame and glass removed) first enter the twin shaft shredder to be torn into strips. Following this, the material moves to the crusher, which reduces the material into small pieces of 1-2 cm.

4.Fine Grinding and Air Separation: These small pieces are fed via negative pressure into the Fine grinder. Our fine grinder is configured with a return material system to re-process any particles that do not meet the size requirements. Qualified material then enters the air separator, which screens out the metal powder from one side, separating it from the plastic and remaining small amount of metal on the other side.

5.Final Electrostatic Sorting: The mixture of plastic and trace metal is then directed to the electrostatic separator. This highly efficient step ensures that pure plastic and high-purity metal are precisely sorted and recovered, finalizing the high-grade output.

Parameter

| Model | Capacity | Power | Weight | Dimension(m) |

| SOLAR-1500 | 1500-200 Kg/H | 315 KW | 11 Ton |

36*8*5

|

Our Solar Panel Recycling Machine offers significant advantages:

1.Fully Automated and High Efficiency: The process design is fully automated, significantly reducing labor costs and accelerating the processing speed to enhance overall production efficiency.

2.Eco-Friendly Physical Process: The entire system relies on purely physical means. Crucially, the equipment is equipped with dust removal equipment, ensuring no dust and pollution occur during the working process.

3.High-Purity Final Products: The integrated crushing and sorting processes yield high-quality output materials, including high-purity metal powder and plastic.

-

Complete PV Module Processing

Designed to recycle end-of-life crystalline silicon solar panels, including aluminum frames, glass, silicon cells, plastics, and metals. -

High Material Recovery Rate

Advanced crushing and separation technology enables efficient recovery of glass, aluminum, copper, and silicon-based materials. -

Modular Plant Design

The recycling plant adopts a modular structure, allowing flexible capacity configuration and easy expansion according to project needs. -

Low Energy Consumption

Optimized process flow and energy-efficient equipment reduce overall power consumption and operating costs. -

High Level of Automation

Automated feeding, shredding, and separation systems minimize manual labor and ensure stable, continuous operation. -

Environmentally Friendly Operation

Dust control, noise reduction, and enclosed systems help the plant comply with environmental protection standards. -

Stable and Durable Equipment

Heavy-duty construction and wear-resistant components ensure long service life and reliable performance. -

Customizable Output Materials

Output size and purity of recovered materials can be adjusted to meet different downstream recycling or reuse requirements. -

Easy Operation and Maintenance

User-friendly control systems and well-designed equipment layout simplify operation, inspection, and maintenance. -

Complete Technical Support from Suny Group

Suny Group provides full project services, including plant design, equipment supply, installation guidance, and after-sales support.