Fully Automatic Solar Pv Panel Recycling Plant is an advanced solution designed to process end-of-life solar modules efficiently, safely, and sustainably. With the rapid growth of the solar energy industry, large quantities of obsolete and damaged PV panels are entering the waste stream. This fully automatic recycling plant provides a professional and environmentally responsible way to recover valuable materials while minimizing manual labor and operational risks.

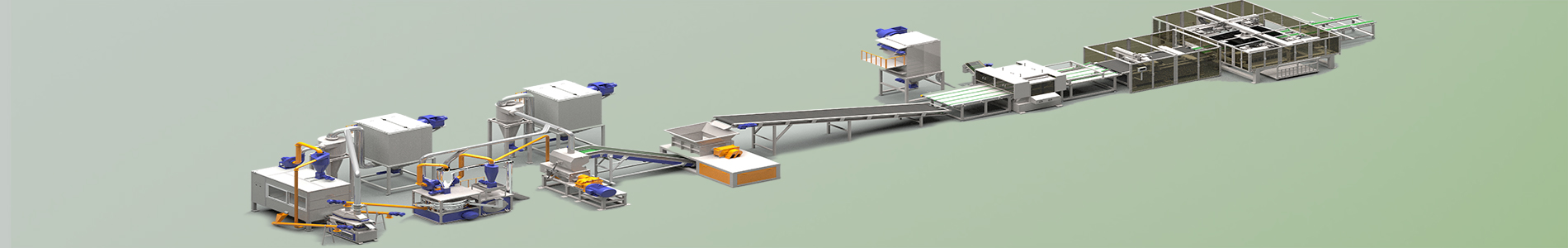

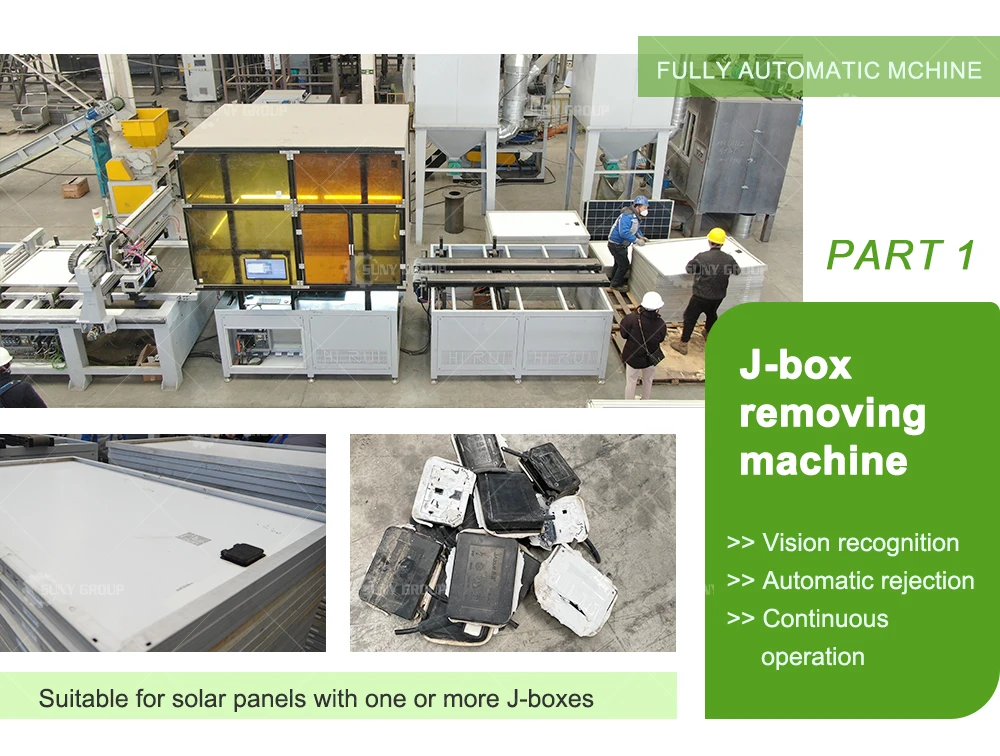

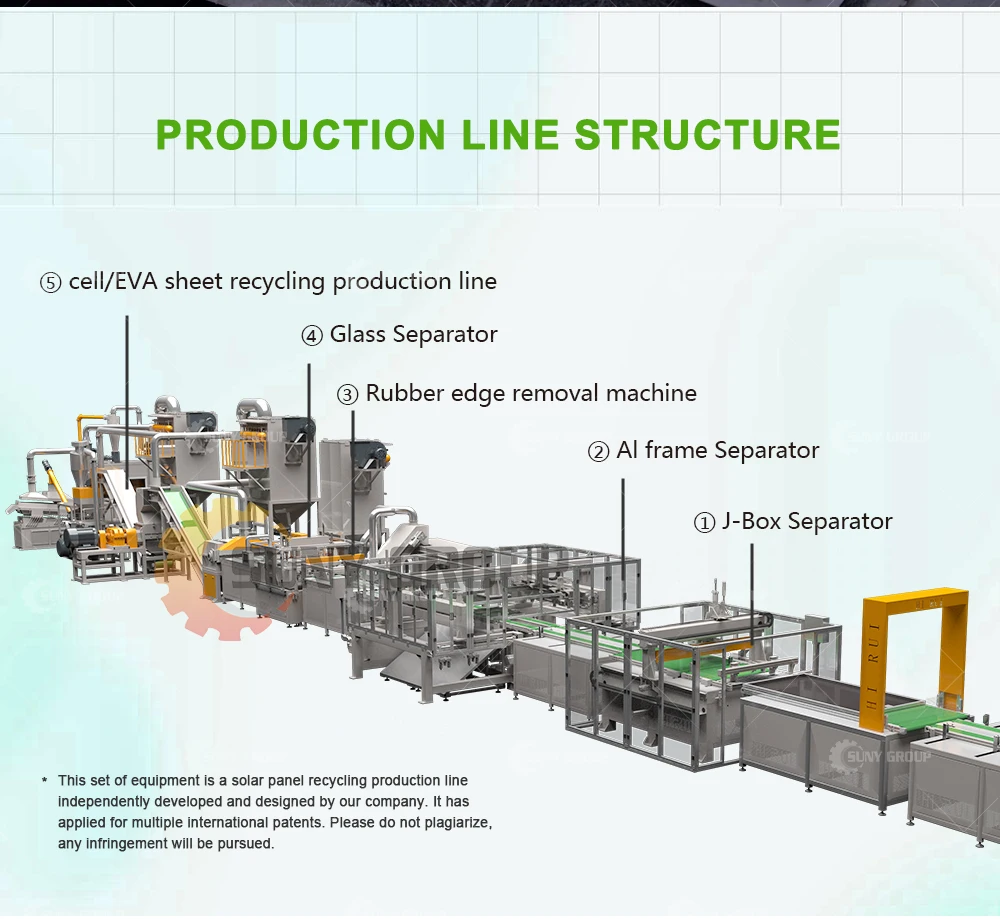

The recycling process begins with automatic feeding and precise dismantling of photovoltaic panels. Aluminum frames and junction boxes are removed efficiently, allowing clean separation of reusable aluminum and copper components. The remaining panel structure is then processed through advanced crushing and size reduction systems, ensuring consistent particle size for downstream separation. Automated conveying systems ensure smooth material flow throughout the entire recycling line.

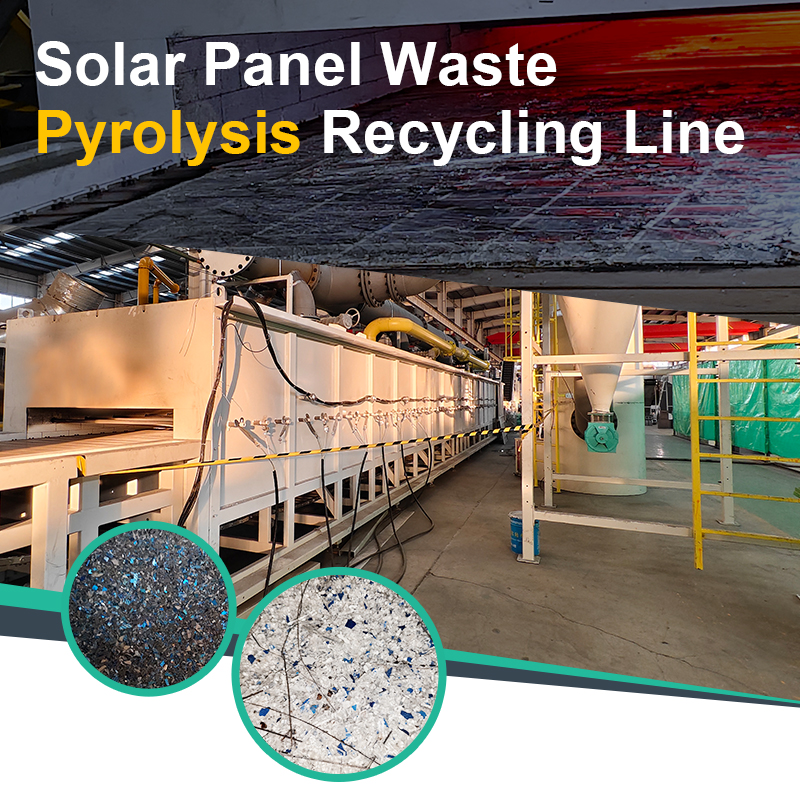

One of the core advantages of a fully automatic solar and PV panels recycling plant is its high material recovery rate. Through multi-stage separation technologies such as magnetic separation, air classification, and screening, the plant effectively separates glass, metals, and composite materials. Advanced configurations may integrate thermal or delamination technologies to further recover high-value materials such as silicon and silver, significantly increasing overall recycling efficiency and economic return.

Automation plays a critical role in improving safety and productivity. Intelligent control systems monitor operating parameters in real time, reducing human intervention and ensuring stable performance. Compared with semi-automatic systems, fully automatic plants offer lower labor costs, higher throughput, and more consistent output quality, making them ideal for medium- to large-scale recycling operations.

Environmental protection is a key design focus of the fully automatic PV panels recycling plant. Integrated dust collection, noise reduction, and enclosed processing systems ensure compliance with environmental regulations. Clean and controlled operation helps recycling companies meet sustainability goals while supporting the circular economy of the renewable energy industry.

In conclusion, Fully Automatic Solar Pv Panel Recycling Plant combines high automation, efficient material recovery, and eco-friendly operation. It is a reliable and future-oriented solution for recycling enterprises seeking long-term profitability and sustainable development in the growing solar energy recycling market.

Parameter

| Model | Capacity | Power | Weight | Dimension(m) |

| SOLAR-1500 | 1500-200 Kg/H | 315 KW | 11 Ton |

36*8*5

|

RECYCLING TECHNOLOGY

The rest of the components in a solar panel consist of good quality glass, aluminium frames, polymers,silicon, copper and silver paste (used for the printed conductors on each cell), all of which (up to 95%), can in principle be successfully recycled.

-

Fully Automated Operation

The entire recycling process runs automatically, reducing manual intervention and improving operational safety and consistency. -

Automatic Panel Feeding System

Solar panels are fed into the line continuously, ensuring stable throughput and high processing efficiency. -

Precise Aluminum Frame Removal

Dedicated dismantling units separate aluminum frames accurately, producing clean and reusable aluminum output. -

Efficient Junction Box Separation

The system removes junction boxes and cables efficiently, allowing effective copper recovery. -

Multi-Stage Crushing Technology

Advanced crushing units reduce panel materials to suitable sizes for downstream separation. -

High-Accuracy Material Separation

Magnetic separation, air classification, and screening ensure clean separation of glass and metals. -

High Material Recovery Rate

Valuable materials such as glass, aluminum, copper, and silicon are recovered with high purity. -

Intelligent PLC Control System

Real-time monitoring and automatic adjustment ensure stable operation and reduced downtime. -

Environmentally Friendly Design

Enclosed structures with dust collection systems minimize pollution and meet environmental standards. -

Modular and Scalable Structure

The plant design allows easy capacity expansion to adapt to different recycling demands.