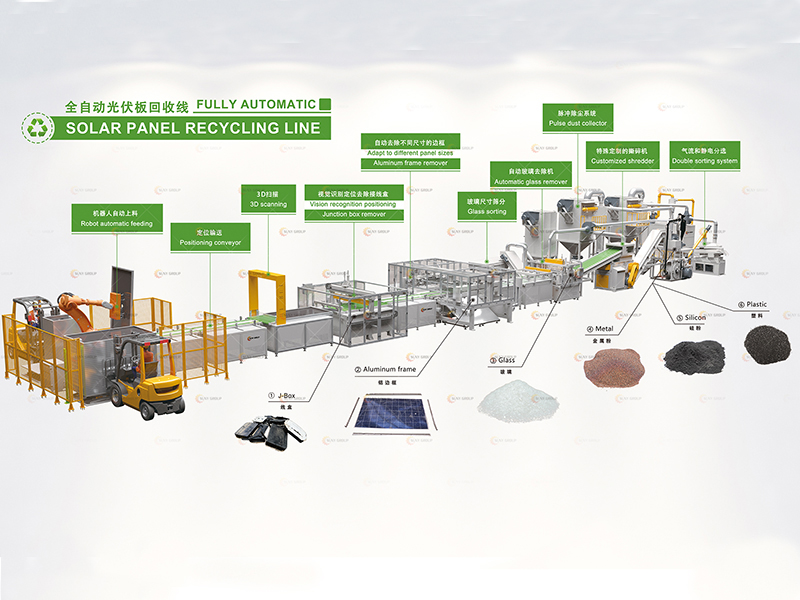

Full Production Line of Solar Panels Recycling

Full production line of solar panels recycling is essential for managing the growing volume of end-of-life photovoltaic (PV) modules worldwide. As solar energy continues to expand, millions of panels reach their service limit every year, making efficient recycling technologies more critical than ever. This article introduces the complete workflow, core equipment, material recovery steps, and the environmental benefits of using an integrated solar panel recycling line.

1. Solar Panel Recycling Equipment Overview

A modern full production line of solar panels recycling uses a combination of specialized machines designed to dismantle, crush, sort, and recover valuable materials from discarded PV modules. Key solar panel recycling equipment includes automatic frame removal machines, junction-box detachers, glass separation systems, shredders, crushers, and material classification systems. These components work together to maximize recovery efficiency while minimizing operational costs and labor input.

2. Photovoltaic Module Dismantling System

The recycling process begins with a photovoltaic module dismantling system, which removes aluminum frames, cables, and electrical boxes.

Typical dismantling steps include:

-

Automatic frame cutting without damaging internal layers

-

Junction-box heating and separation for cleaner removal

-

Cable stripping to obtain high-purity copper

This stage ensures that the remaining laminated panel is ready for controlled mechanical treatment.

3. Solar Panel Crushing and Separation Line

After dismantling, the laminated PV sheet moves into the solar panel crushing and separation line. This system uses primary shredders, hammer mills, and fine crushers to reduce the glass–EVA–cell layers into manageable particles. The line is engineered to protect the high-value materials during crushing.

The separation process typically includes:

-

Density separation to extract clean glass

-

Magnetic separation for ferrous metals

-

Eddy current separation for aluminum fragments

-

Airflow classification for collecting light plastics and dust

This ensures a high recovery rate of both glass and metals.

4. EVA and Glass Recovery Process

One of the most important parts of a full production line of solar panels recycling is the EVA and glass recovery process. These laminated layers are difficult to separate, but advanced heating and peeling technologies allow nearly 100% recovery.

Key results:

-

High-purity glass, usable for fiberglass, construction materials, and new solar modules

-

Separated EVA, suitable for fuel use, pyrolysis treatment, or secondary material production

This maximizes the economic value of recycled materials.

5. End-of-Life PV Module Recycling Technology

Modern end-of-life PV module recycling technology focuses on high efficiency, low emissions, and automation. Many recycling lines now integrate AI sorting, dust-free conveying, closed-loop air filtration, and remote control systems. These features help factories achieve stable operation, minimal downtime, and compliance with environmental regulations.

6. Benefits of a Full Production Line of Solar Panels Recycling

A complete solar panel recycling line provides significant environmental and economic benefits:

-

Reduces landfill waste

-

Recovers valuable materials such as glass, silver, copper, and aluminum

-

Supports circular economy development

-

Lowers carbon emissions from manufacturing

-

Helps solar farms and EPC firms meet recycling regulations

-

Provides high profitability for recycling companies

A full production line of solar panels recycling is an essential solution for the growing global demand for sustainable PV waste management. Its advanced equipment, efficient separation systems, and high material-recovery rates make it a key technology in the future of renewable energy recycling.