When a Japanese customer first submits an inquiry for a solar panel recycling machine, providing a fast and professional response is the foundation of successful cooperation. From the initial demand to final installation, a complete service process ensures that the recycling system fully meets technical, environmental, and operational requirements.

Early Communication and Demand Confirmation

At the first stage, our team contacts the Japanese customer promptly to understand detailed project requirements. This includes the type of waste solar panels, expected processing capacity, factory layout, local safety standards, and environmental regulations in Japan. Clear and timely communication helps eliminate misunderstandings and ensures that all technical details are accurately confirmed at an early stage.

Customized Recycling Solution Proposal

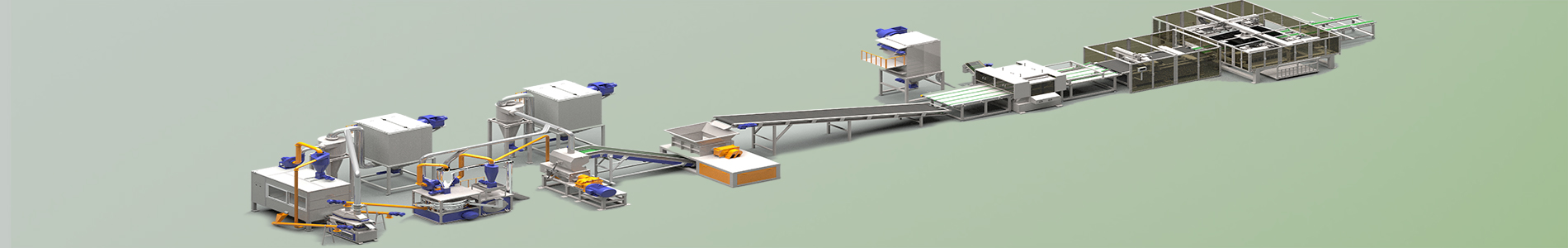

Based on the customer’s specific needs, a customized solar panel recycling solution is designed. The proposed system includes processes such as frame removal, glass separation, crushing, and material sorting. Special attention is given to automation level, dust collection systems, noise control, and energy efficiency, which are highly valued by Japanese customers. Layout drawings and process flow diagrams are provided to help the customer fully understand the recycling line.

Continuous Improvement Based on Customer Feedback

After presenting the initial solution, customer feedback is carefully reviewed. Machine configuration, capacity, and safety features are adjusted to better match operational habits and site conditions. This step-by-step optimization ensures that the final solar panel recycling machine design fully satisfies the customer’s expectations and complies with local standards.

Manufacturing, Inspection, and Delivery

Once the final solution is approved, the equipment enters the production stage. Strict quality control and pre-shipment testing are carried out to ensure stable and reliable performance. After inspection, the recycling machine is safely packed and shipped to Japan with complete technical documentation.

Installation, Commissioning, and Training

After arrival, professional engineers assist with installation and commissioning, either on-site or through remote guidance. The recycling line is tested under real operating conditions to ensure smooth operation. At the same time, operators receive detailed training on machine operation, maintenance, and safety procedures.

Conclusion

From the first communication to final installation, a complete and customer-oriented service process ensures that each solar panel recycling machine delivered to Japanese customers achieves high efficiency, reliability, and long-term operational value.

-

Fast Response to Customer Demand

Immediate communication after receiving Japanese customer inquiries ensures accurate understanding of technical and operational requirements. -

Customized Recycling Solution

The recycling line is tailored according to panel type, capacity, site layout, and local regulations, ensuring a perfect fit for the customer’s project. -

Compliance with Japanese Environmental Standards

The system is designed to meet strict Japanese requirements for dust control, noise reduction, and workplace safety. -

High Automation and Stable Operation

Automated processes reduce labor dependency and ensure consistent, long-term operational stability. -

Efficient Material Recovery

High recovery rates for glass, aluminum, and silicon maximize recycling value and improve overall project profitability. -

Flexible System Configuration

Machine layout and capacity can be adjusted or upgraded based on future expansion needs. -

Strict Quality Control and Testing

Each solar panel recycling machine undergoes factory testing and inspection before delivery to ensure reliable performance. -

Professional Installation and Commissioning Support

Experienced engineers provide on-site or remote guidance to ensure smooth installation and rapid startup. -

Comprehensive Operator Training

Detailed training on operation, maintenance, and safety helps customers quickly master the system and reduce downtime. -

Long-Term After-Sales Service

Continuous technical support, spare parts supply, and maintenance guidance ensure stable operation and long equipment lifespan.

Next: