Solar Panel Recycling Plant Cost in India

As India rapidly expands its solar energy capacity, the management of end-of-life solar photovoltaic (PV) modules has emerged as a growing environmental and economic challenge. With an estimated installed PV capacity exceeding 60 GW and rising, a significant volume of discarded panels is expected over the next decades, creating both waste management needs and recycling market opportunities in India.

Current Solar PV Waste Situation in India

Solar PV modules typically have a lifespan of 25–30 years. As earlier installations reach their end of life, India will face rapidly increasing solar waste. Studies suggest that by 2047, the country could generate around 11 million tonnes of solar module waste, most of which will consist of crystalline silicon panels. While infrastructure for recycling is currently limited, regulatory frameworks under the E-Waste (Management) Rules, 2022 now classify PV modules as e-waste, laying the legal groundwork for formal recycling and collection systems.

Recycling Prospects in India

The solar panel recycling industry in India is still in its infancy. Recycling creates potential environmental benefits by diverting heavy glass and metals from landfills and recapturing materials like aluminum, silicon, copper, and silver. Globally, the value of recoverable materials from retired PV panels is forecast to grow substantially as panel volumes increase. However, the economics at present are challenging: high procurement, collection, and processing costs often outweigh revenues from recovered materials, especially when recycling is done without supportive policies.

Despite current financial barriers, long-term prospects are positive. India’s solar waste management market could represent a multibillion-rupee opportunity by mid-century if recycling infrastructure and policy support expand.

Recycling Plant Configuration & Cost in India

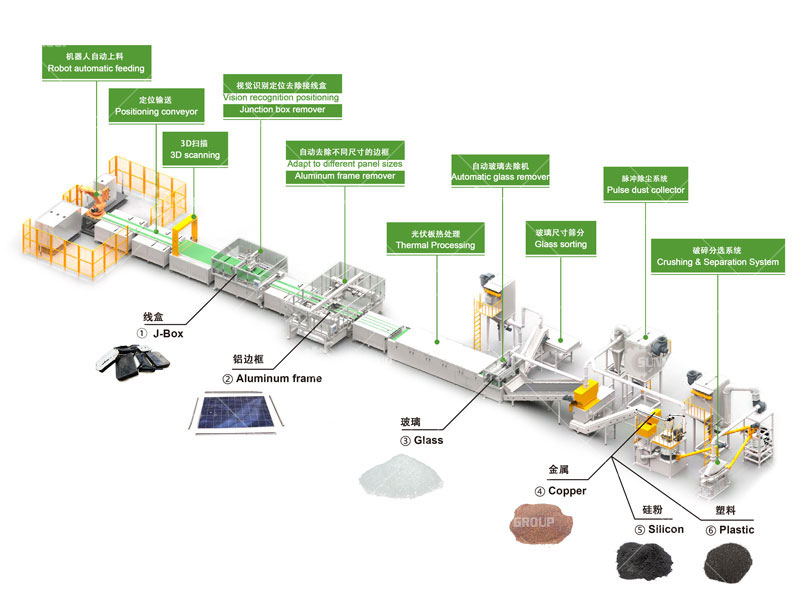

Setting up a solar panel recycling plant in India involves significant capital expenditure. A standard facility includes:

-

Reception & Pre-Processing Area: Unloading and initial sorting

-

Mechanical Processing Systems: Shredders, crushers, separation equipment

-

Delamination & Thermal Systems: High-temperature furnaces or kilns for removing encapsulants

-

Chemical Processing Units (optional): For extracting higher-grade materials

-

Emission Control and Wastewater Treatment: Environmentally safe operations

Capital costs for this equipment can range widely: reception infrastructure might cost ₹50 lakhs to ₹2 crore, while advanced delamination and thermal systems can add ₹2–8 crore depending on capacity and technology choices. Complete chemical processing systems further increase investment needs.

Operational expenses include collection, transportation, labor, utilities, maintenance, and disposal of non-recoverable waste. At present, recycling costs average ₹25,000–30,000 per tonne of solar panels processed, or roughly ₹600–750 per panel, under current logistics and market conditions in India.

Materials Recovered and Value

Solar panel recycling primarily targets several key materials:

-

Glass (~70–76%): Large percentage by weight, though often lower quality than virgin glass.

-

Aluminum (~8–10%): From frames, with substantial resale value.

-

Copper (~1%): From internal wiring and connections.

-

Silicon (~3–5%): Recovered from cells, though often at lower grade unless refined.

-

Silver (~0.02%): A minor component by weight but high in value if efficiently extracted.

Under optimistic recovery rates, the total material value per tonne of processed waste can exceed ₹30,000, driven by aluminum and precious metal recovery.

Profitability and Economic Outlook

Currently, formal solar panel recycling in India tends to be financially unviable without supportive mechanisms, with recycling costs exceeding material revenues and resulting in losses. However, if waste panels are supplied at low or no cost to recyclers, or if Extended Producer Responsibility (EPR) incentives are introduced and enforced, recyclers can achieve positive margins.

In the long term, as panel volumes increase, technologies improve, and policies evolve — combined with rising prices for virgin materials — solar panel recycling is expected to become progressively more profitable, helping India build a circular economy around its expanding solar infrastructure.