Solar Panel Recycling Plant

Solar panel recycling plant plays a critical role in managing the rising volume of end-of-life photovoltaic modules. As global solar installations expand, millions of panels will reach retirement age in the coming years, creating both environmental challenges and new opportunities for material recovery.

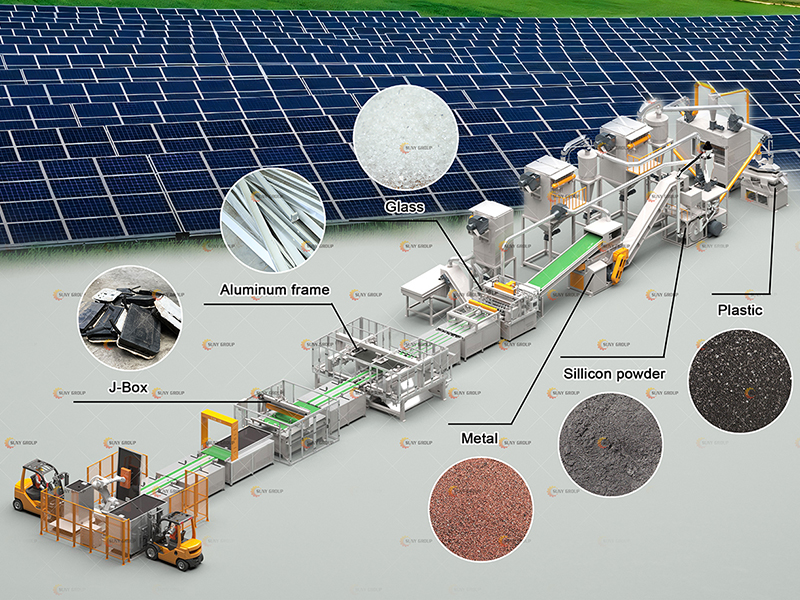

1. Growing Need for Solar Panel Recycling Plants

The rapid expansion of global solar energy has led to a significant increase in photovoltaic waste. Most solar panels have a lifespan of 20–30 years, meaning early-generation panels are starting to reach end-of-life. Many countries also enforce strict environmental regulations that prohibit landfilling or improper disposal. As a result, building a solar panel recycling plant becomes essential for sustainable waste management and valuable resource recovery.

2. Components of Solar Panels and Recoverable Materials

A solar panel contains several high-value materials that can be efficiently recovered:

-

Tempered glass (about 70% of total weight)

-

Silicon wafers, often in monocrystalline or polycrystalline form

-

Aluminum frames

-

Copper wires and silver conductors

-

EVA encapsulant and backsheet materials

These components hold significant reuse value. Glass can be remanufactured, aluminum can be melted and reused, and recovered silicon can enter the semiconductor or renewable energy industries.

3. Core Recycling Processes Used in a Solar Panel Recycling Plant

Modern solar panel recycling plants use a combination of mechanical and thermal technologies:

-

Pre-processing – Removing aluminum frames and junction boxes.

-

Primary crushing – Breaking modules into smaller pieces for separation.

-

Mechanical sorting – Magnetic separation, eddy current separation, and air classification to isolate metals and glass.

-

Thermal treatment or pyrolysis – Heating panels to remove EVA bonding layers and release clean silicon wafers.

-

Optical and density-based separation – Achieving higher purity for silicon and conductive metals.

A well-designed recycling line ensures high recovery rates and stable operation.

4. Key Machines and Equipment in a Solar Panel Recycling Plant

A complete recycling plant includes specialized machines such as:

-

Frame removal machines

-

Junction box cutting systems

-

Solar panel crushers and shredders

-

Magnetic separators and eddy current separators

-

High-temperature pyrolysis furnaces

-

Glass cleaning and grading systems

-

Dust removal and automated conveyor systems

These machines work together to achieve efficient, continuous, and eco-friendly material recovery.

5. Final Recycled Products and Industrial Applications

Recycled materials from solar panels have wide industrial uses:

-

Glass – Building materials, insulation products, and even new PV glass

-

Silicon – Reused in solar wafer production and electronic components

-

Aluminum – New PV frames, industrial profiles, and automotive parts

-

Copper and silver – Electronic circuits, soldering materials, and electrical components

-

Composites – Potential use in fillers, construction boards, and engineered materials

The recovered value supports sustainable and profitable recycling operations.

6. Economic Feasibility and Environmental Benefits

A solar panel recycling plant offers strong commercial potential. Recovered materials—especially aluminum, glass, and high-purity silicon—provide stable revenue. In addition, recycling reduces landfill waste, cuts carbon emissions, and supports government ESG requirements. Many countries offer subsidies and incentives to encourage investment in renewable energy recycling.