Solar Panel Dismantling Machine for PV Modules

As global solar installations continue to grow rapidly, a large number of photovoltaic (PV) modules are approaching the end of their service life. Efficient recycling has become a critical issue for the renewable energy industry. solar panel dismantling machine for PV modules is specifically designed to separate and recover valuable materials from waste solar panels, supporting sustainable development and circular resource utilization.

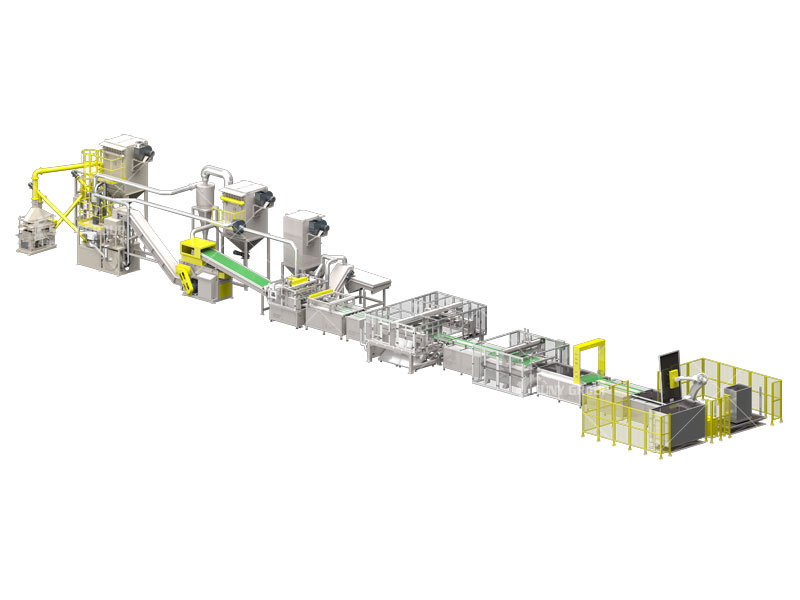

1. What Is a Solar Panel Dismantling Machine for PV Modules

A solar panel dismantling machine for PV modules is specialized recycling equipment used to dismantle end-of-life or defective photovoltaic panels. Its main purpose is to safely and efficiently separate aluminum frames, junction boxes, cables, glass, and internal composite layers without excessive material loss.

Compared with manual dismantling, this machine offers higher efficiency, stable output quality, and improved safety. It is widely used in solar panel recycling plants, waste electronic recycling centers, and renewable energy recovery projects.

2. Why PV Module Dismantling Is Becoming Increasingly Important

The importance of PV module dismantling continues to rise due to several factors:

-

The global installed capacity of solar power is expanding every year

-

Early-generation PV modules are reaching 20–30 years of service life

-

Landfilling solar panels causes long-term environmental risks

-

PV modules contain valuable recyclable materials

Using a solar panel dismantling machine for PV modules helps reduce waste, comply with environmental regulations, and recover reusable resources efficiently.

3. Main Components and Technical Features of Solar Panel Dismantling Machines

A typical solar panel dismantling machine for PV modules includes:

-

Frame removal system for aluminum frames

-

Junction box separation unit for cables and connectors

-

Conveyor and feeding system for continuous operation

-

High-strength cutting or dismantling tools for panel structure separation

-

Dust control and safety protection system

These machines are designed for stable operation, low energy consumption, and compatibility with different PV panel sizes and structures.

4. Working Process of a Solar Panel Dismantling Machine for PV Modules

The dismantling process generally follows these steps:

-

Feeding

Waste PV modules are placed onto the feeding conveyor. -

Aluminum Frame Removal

The machine automatically separates aluminum frames from the panels. -

Junction Box Separation

Junction boxes and cables are detached for independent recycling. -

Panel Disassembly

The remaining PV laminate is prepared for further crushing or separation processes.

This standardized process improves efficiency and reduces manual labor requirements.

5. Recovered Materials and Their Industrial Applications

Materials recovered by a solar panel dismantling machine for PV modules include:

-

Aluminum frames: reused in construction, automotive, and metal processing industries

-

Glass: used for glass manufacturing, construction materials, and insulation products

-

Copper cables: recycled for electrical and electronic applications

-

Silicon-containing laminates: further processed in advanced PV recycling lines

These recycled materials significantly reduce the need for virgin raw materials.

6. Advantages of Using a Dedicated Solar Panel Dismantling Machine

Using a dedicated solar panel dismantling machine for PV modules offers clear advantages:

-

High dismantling efficiency and stable output

-

Reduced labor cost and improved workplace safety

-

Higher recovery rate of valuable materials

-

Easy integration with complete solar panel recycling lines

-

Long-term economic and environmental benefits

Conclusion

A solar panel dismantling machine for PV modules is essential equipment for modern photovoltaic recycling. It enables efficient dismantling, high-value material recovery, and environmentally responsible waste management. As solar energy continues to expand worldwide, investing in professional PV dismantling technology is a crucial step toward sustainable and profitable solar panel recycling operations.

Next: