Solar Panel Crushing Recycle Plant

Solar panel crushing recycle plant is a specialized system designed to process end-of-life photovoltaic modules and recover valuable materials. As the global installation of solar energy systems continues to grow, the number of discarded solar panels is increasing rapidly. Efficient recycling plants are essential for reducing environmental impact and improving resource utilization.

What Is a Solar Panel Crushing Recycle Plant?

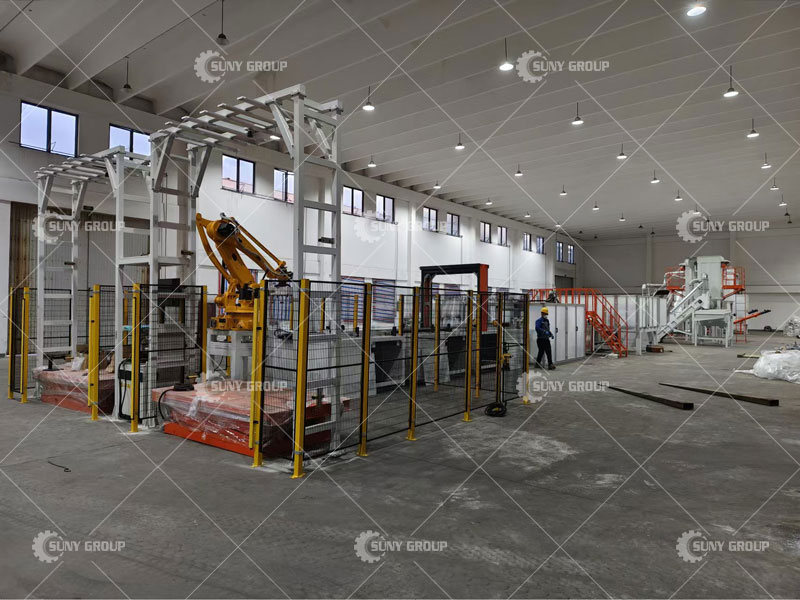

Solar panel crushing recycle plant is an integrated recycling line that dismantles, crushes, and separates solar panel components. The plant is engineered to handle framed and frameless photovoltaic modules, ensuring safe and efficient processing.

The recycling process allows the recovery of glass, aluminum, copper, and silicon materials, transforming waste solar panels into reusable industrial resources.

Main Components of a Solar Panel Crushing Recycle Plant

A complete solar panel crushing recycle plant typically consists of the following core systems:

-

Frame Removal Unit: Separates aluminum frames efficiently

-

Junction Box Treatment System: Removes cables and connectors

-

Primary Crushing Equipment: Breaks panels into manageable sizes

-

Secondary Grinding System: Further reduces particle size

-

Separation Units: Includes screening, magnetic, and air separation

-

Dust Collection System: Ensures clean and compliant operation

Each component works together to achieve high recovery rates and stable performance.

Working Process of a Solar Panel Crushing Recycle Plant

The working process begins with manual or automated feeding of waste solar panels. Aluminum frames and junction boxes are removed first to prevent equipment damage. The remaining panels enter the crushing chamber, where they are broken into smaller fragments.

After crushing, the material is ground into fine particles. Advanced separation systems then classify and separate glass, metals, and non-metallic materials. The entire process is designed for continuous operation with minimal material loss.

Applications of Recycled Solar Panel Materials

Materials recovered by a solar panel crushing recycle plant are widely used in various industries:

-

Recycled Glass Production

High-purity glass can be reused in construction and manufacturing. -

Aluminum Reprocessing

Aluminum frames are remelted and reused in metal industries. -

Copper Recovery

Extracted copper is suitable for cable and electrical applications. -

Silicon Material Reuse

Processed silicon can be refined for industrial use.

These applications significantly improve the economic value of solar panel recycling.

How to Choose the Right Solar Panel Crushing Recycle Plant

When selecting a solar panel crushing recycle plant, several key factors should be considered:

-

Daily processing capacity and automation level

-

Compatibility with different solar panel types

-

Recovery efficiency of valuable materials

-

Energy consumption and operating cost

-

Environmental compliance and dust control

A well-designed plant ensures stable operation and long-term profitability.

Advantages of a Solar Panel Crushing Recycle Plant

Using a solar panel crushing recycle plant provides multiple benefits:

-

Reduces photovoltaic waste sent to landfills

-

Maximizes recovery of valuable raw materials

-

Supports circular economy and sustainability goals

-

Meets environmental and recycling regulations

These advantages make solar panel recycling plants essential for renewable energy waste management.

Solar panel crushing recycle plant is a vital solution for managing end-of-life photovoltaic modules. With efficient crushing, advanced separation, and high recovery rates, it transforms solar panel waste into valuable resources. Investing in a reliable solar panel crushing recycle plant supports environmental protection while creating sustainable economic returns.