Solar Module Recycling Line Manufacturer

1. Definition of a Solar Module Recycling Line Manufacturer

Solar module recycling line manufacturer specializes in designing and producing complete recycling systems for end-of-life photovoltaic (PV) panels. These manufacturers provide integrated solutions that safely dismantle solar modules and recover valuable materials such as aluminum frames, glass, silicon cells, copper, and silver. With the rapid growth of the solar industry, professional recycling line manufacturers play a critical role in supporting sustainable energy development and circular resource utilization.

2. Sources and Challenges of Waste Solar Modules

Waste solar modules mainly come from aging photovoltaic power plants, damaged panels, manufacturing defects, and system upgrades. As solar panels typically have a lifespan of 25–30 years, large volumes are now entering the recycling stage. The main challenge lies in separating laminated materials efficiently while minimizing environmental impact. A reliable solar module recycling line manufacturer develops equipment that addresses these challenges through automation, safety, and precise separation technology.

3. Why Choosing a Professional Recycling Line Manufacturer Matters

Selecting an experienced solar module recycling line manufacturer ensures stable operation, high recovery rates, and compliance with environmental regulations. Professional manufacturers offer customized solutions based on capacity requirements, panel types, and local standards. Their systems are designed to reduce manual labor, lower operational risks, and improve material purity, helping recycling companies achieve long-term profitability and regulatory approval.

4. Solar Module Recycling Line Process and Technology

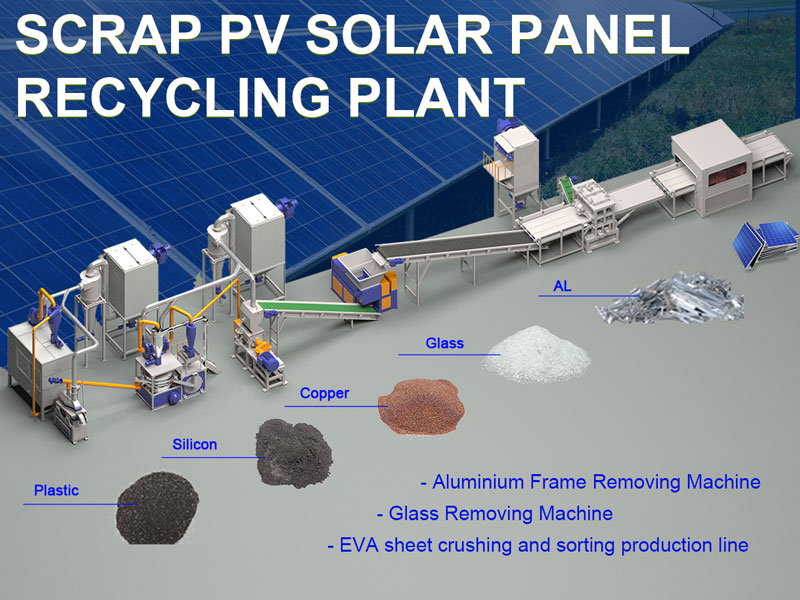

A complete recycling line usually follows a systematic process.

-

First, solar modules are fed into a frame removal unit to separate aluminum frames.

-

Next, the panels enter a crushing and shredding system to break the laminated structure.

-

Advanced separation technologies, including screening, air separation, and electrostatic sorting, are then applied.

-

Glass, metals, and silicon materials are accurately classified and collected.

An advanced solar module recycling line manufacturer integrates intelligent control systems and dust collection units to ensure safe, efficient, and environmentally friendly operation throughout the process.

5. Output Materials and Their Industrial Applications

High-quality output is a key advantage offered by a professional manufacturer. Recovered aluminum frames are clean and suitable for direct remelting. Glass output reaches high purity and can be reused in construction materials or new solar glass production. Silicon and metal components such as copper and silver are valuable secondary resources for electronics and metallurgical industries. Clean and stable output significantly increases the economic value of solar module recycling projects.

6. Future Trends of Solar Module Recycling Line Manufacturers

As global photovoltaic installations continue to grow, the demand for advanced recycling solutions will increase rapidly. Future solar module recycling line manufacturers will focus on higher automation, smarter sorting technology, and improved recovery efficiency. Energy-saving designs and modular equipment will become standard, enabling flexible expansion and lower operating costs. Manufacturers that invest in innovation and sustainability will lead the global solar recycling market.

Conclusion

Professional solar module recycling line manufacturer is essential for efficient, compliant, and profitable photovoltaic waste management. By providing advanced technology, clean output, and reliable performance, these manufacturers support the sustainable development of the solar energy industry worldwide.