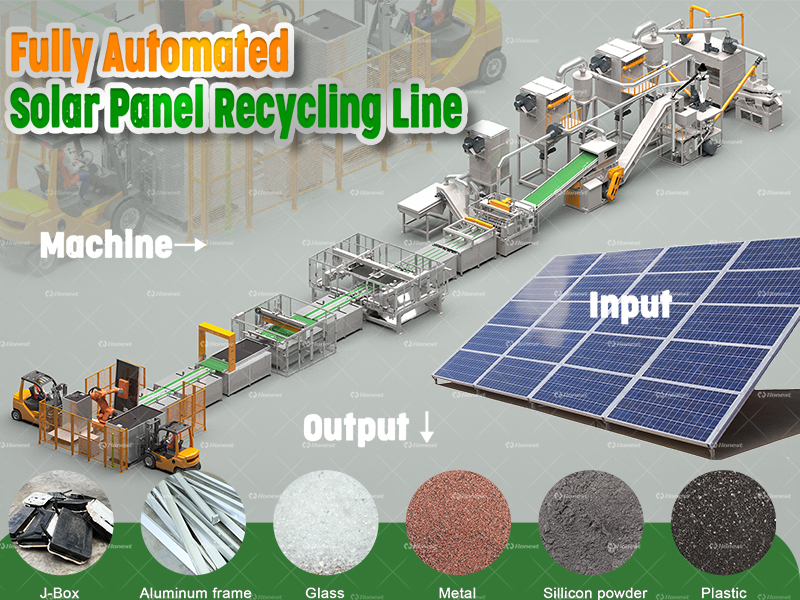

Fully Automated Solar Panel Recycling Machine

Fully automated solar panel recycling machine is a modern and efficient solution designed to address the rapidly growing volume of end-of-life photovoltaic (PV) modules. As global solar installations continue to expand, the demand for reliable and sustainable recycling equipment is increasing. This machine integrates advanced shredding, separation, and purification technologies to recover valuable materials such as glass, aluminum, silicon, copper, and silver. Its automated system minimizes labor requirements while maximizing recovery rates, making it an essential part of today’s circular solar economy.

1. Key Recycling Technologies and Process Flow

The fully automated solar panel recycling machine adopts a complete and optimized recycling process to ensure high-quality material recovery. The typical process includes several core steps:

-

Automated Panel Feeding and Pre-Shredding

Solar panels are transported to the machine through an automated feeder, where a powerful shredder breaks them into uniform pieces to prepare for further separation. -

Precise Material Separation Technology

Advanced mechanical, magnetic, and optical separation methods are used to extract aluminum frames, copper wires, backsheet materials, and tempered glass. A specialized delamination system separates the EVA layer and silicon wafers with minimal contamination. -

Dust Control and Purification Units

Integrated dust collectors and filtration systems prevent secondary pollution, ensuring a clean and safe industrial recycling environment.

This structured process ensures the machine can operate continuously, increasing productivity and reducing operational costs.

2. High Efficiency and Large Processing Capacity

One of the most significant advantages of a fully automated solar panel recycling machine is its high throughput and stable performance. It can process large quantities of discarded solar modules per hour, making it suitable for industrial-scale recycling plants and national renewable-energy waste projects.

High-efficiency motors, optimized cutters, and automated conveyors allow continuous operation with minimal downtime. Since the system performs feeding, crushing, and separation automatically, human intervention is greatly reduced. This not only enhances safety but also lowers long-term labor expenses. The machine’s durable structure and wear-resistant components ensure long service life and reliable daily operation, even under heavy loads.

3. Environmental Benefits and Waste Reduction

The fully automated solar panel recycling machine plays a critical role in promoting environmental sustainability. Solar modules contain valuable materials that can be recycled repeatedly, reducing the need for new raw resources. By recovering glass, aluminum, and semiconductor materials, the machine significantly decreases landfill waste and prevents harmful components from entering the environment.

Moreover, the machine’s closed-loop dust control, low-energy consumption design, and clean separation process align with global environmental protection standards. It contributes to reducing carbon emissions while supporting the renewable energy industry’s long-term development.

Fully automated solar panel recycling machine is an essential solution for modern PV waste management. With its advanced recycling technology, high efficiency, and significant environmental benefits, it enables recycling companies, solar farms, and waste processing facilities to handle end-of-life solar panels responsibly and profitably. As global solar adoption increases, this machine will continue to play a vital role in building a sustainable and resource-efficient future.