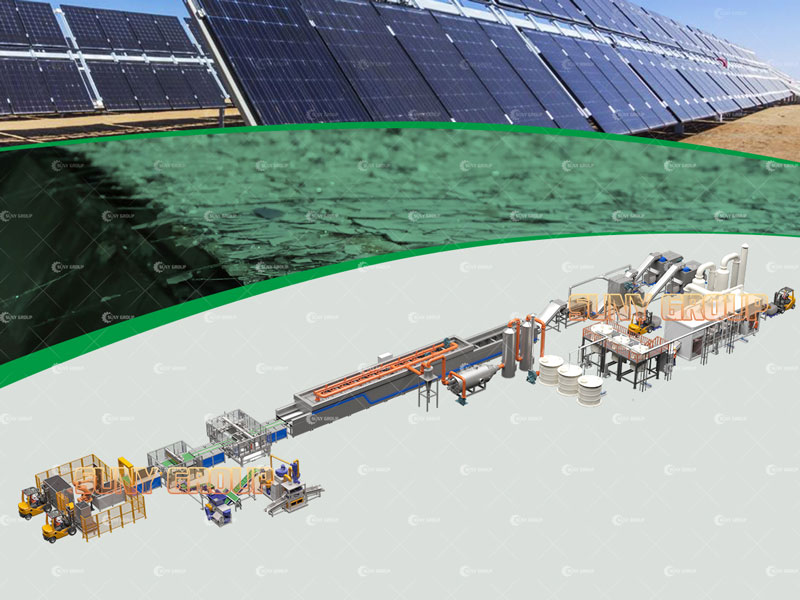

EVA Film Separation Machine for Solar Panels

With the rapid growth of photovoltaic installations worldwide, large volumes of end-of-life solar panels are entering the recycling stage. One of the most challenging components to handle during recycling is the EVA encapsulation layer. EVA film separation machine for solar panels plays a vital role in efficiently separating ethylene-vinyl acetate (EVA) from glass and silicon cells, enabling high-value material recovery.

What Is an EVA Film Separation Machine for Solar Panels

An EVA film separation machine for solar panels is a specialized recycling device designed to remove the EVA film that bonds solar glass, silicon cells, and backsheet materials together. EVA film is highly adhesive and heat-resistant, making manual or conventional mechanical separation inefficient. This machine uses controlled temperature, mechanical force, or chemical-free processes to achieve clean and effective separation, forming a key step in modern solar panel recycling lines.

Why EVA Film Separation Is Critical in Solar Panel Recycling

EVA film separation is essential because EVA strongly adheres to both glass and silicon wafers. Without proper separation:

-

Glass recovery purity is significantly reduced

-

Silicon cells cannot be reused or refined efficiently

-

Recycling costs increase due to contamination

Using an EVA film separation machine for solar panels ensures higher recovery rates, improves material quality, and supports the circular economy by enabling reuse of valuable resources.

Working Principle of an EVA Film Separation Machine

The working process of an EVA film separation machine for solar panels typically includes several steps:

-

Heating or Thermal Softening: The EVA layer is softened under controlled temperature conditions.

-

Mechanical Peeling or Rolling: Specialized rollers or blades gently separate EVA from glass and cells.

-

Continuous Conveying System: Panels move smoothly through the separation chamber for consistent processing.

-

EVA Collection: Separated EVA film is collected independently for further treatment or disposal.

This process avoids excessive damage to glass and silicon, ensuring maximum material value.

Key Features and Technical Advantages

Modern EVA film separation machines offer multiple technical advantages:

-

High Separation Efficiency: Achieves clean separation with minimal residue

-

Energy-Efficient Design: Optimized heating systems reduce energy consumption

-

Stable and Automated Operation: PLC-controlled systems ensure consistent performance

-

Low Environmental Impact: No chemical solvents required during separation

-

Flexible Capacity Options: Suitable for small-scale and industrial recycling plants

These features make EVA film separation machines essential equipment in advanced PV recycling facilities.

Applications and Output Materials After EVA Separation

After processing by an EVA film separation machine for solar panels, recyclers can obtain:

-

High-purity tempered glass for reuse in construction and manufacturing

-

Clean silicon cells suitable for refining or secondary applications

-

Separated EVA film for energy recovery or polymer processing

The improved purity of output materials increases their market value and expands their application range across multiple industries.

How to Choose the Right EVA Film Separation Machine for Solar Panels

When selecting an EVA film separation machine, key factors should be considered:

-

Required processing capacity and panel size compatibility

-

Separation efficiency and residue control performance

-

Energy consumption and operational cost

-

Level of automation and ease of maintenance

-

Compliance with environmental and safety standards

Choosing the right equipment ensures long-term reliability and profitability for solar panel recycling operations.

EVA film separation machine for solar panels is a critical solution for overcoming one of the biggest challenges in photovoltaic recycling. By enabling efficient, clean, and eco-friendly separation of EVA film, this technology significantly improves material recovery rates and supports sustainable development in the solar energy industry. As global demand for solar panel recycling grows, EVA film separation machines will remain a core component of high-performance PV recycling systems.