Complete Production Line for Solar Panel Recycling

1. Definition of a Full Production Line of Solar Panels Recycling

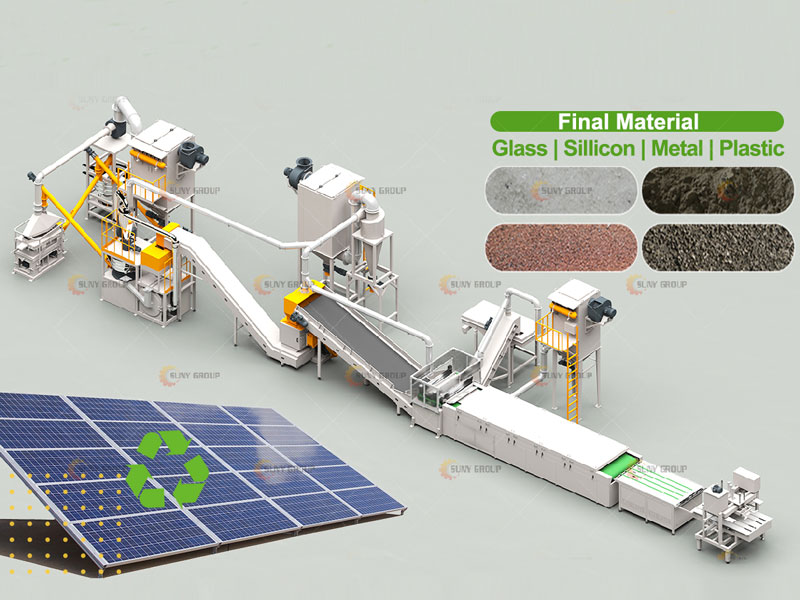

A complete production line of solar panels recycling is a complete industrial system designed to process end-of-life photovoltaic (PV) modules and recover valuable materials. It integrates multiple machines and technologies to dismantle, crush, separate, and refine solar panels efficiently.

With the rapid growth of solar energy installations worldwide, the demand for professional solar panel recycling solutions is increasing. A full production line of solar panels recycling provides a scalable and environmentally responsible way to manage photovoltaic waste.

2. Recycling Process of a Complete Production Line of Solar Panels Recycling

The recycling process of a complete production line of solar panels recycling begins with manual or automatic frame removal. Aluminum frames and junction boxes are separated for direct recycling.

Next, the panels enter crushing and shredding stages, where tempered glass and encapsulated materials are reduced in size. Advanced crushing equipment ensures controlled particle size while minimizing material loss.

After size reduction, separation systems such as vibrating screens, magnetic separators, and air classifiers are used to isolate glass, metals, and polymer materials. This systematic process ensures high recovery efficiency and stable output quality.

3. Main Equipment in a Complete Production Line of Solar Panels Recycling

A typical complete production line of solar panels recycling includes frame removal machines, panel shredders, crushers, hammer mills, and screening units. Each machine is designed specifically for the structure and composition of photovoltaic modules.

Additional equipment such as dust collection systems, intelligent control cabinets, and material conveyors ensure safe and continuous operation. Modern production lines are often equipped with automated controls that reduce labor intensity and improve operational stability.

4. Advantages of a Full Production Line of Solar Panels Recycling

One major advantage of a complete production line of solar panels recycling is its high level of automation, which enables continuous large-scale processing.

The system improves material recovery rates by precisely separating glass, aluminum, silicon, and metals. This leads to higher economic returns for recycling plants.

Moreover, the modular design allows flexible configuration based on capacity requirements and local regulations. Energy-efficient motors and enclosed systems also help reduce operational costs and environmental impact.

5. Output Materials and Applications

The output materials from a complete production line of solar panels recycling mainly include glass, aluminum, copper, silicon powder, and plastic residues.

Recovered glass can be reused in construction materials, insulation products, and new photovoltaic manufacturing. Aluminum and copper are widely applied in metal smelting and industrial production. Silicon materials can be further refined for high-value reuse, supporting resource circularity.

6. Environmental and Economic Value

A complete production line of solar panels recycling delivers significant environmental and economic value. It reduces landfill pressure, lowers carbon emissions, and conserves natural resources.

At the same time, it creates new revenue streams by transforming photovoltaic waste into marketable materials. For governments and recycling companies, investing in a full production line of solar panels recycling supports long-term sustainability and green industry development.

Conclusion

A complete production line of solar panels recycling is an essential solution for managing photovoltaic waste efficiently and sustainably, offering both environmental protection and strong economic benefits.